Online Service Connection < 60s, Email Reply Time < 24h

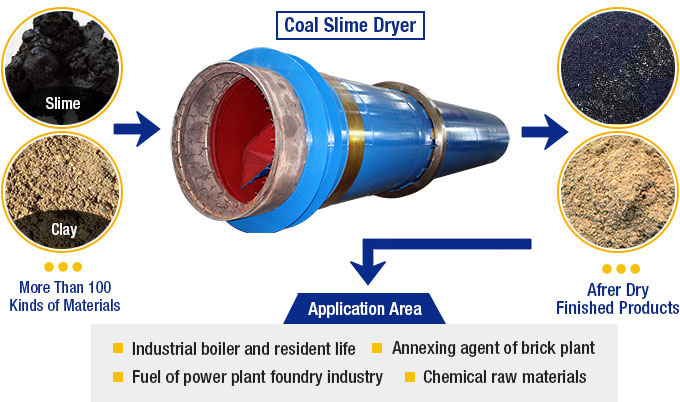

Application area: coal industry, construction industry, mineral industry

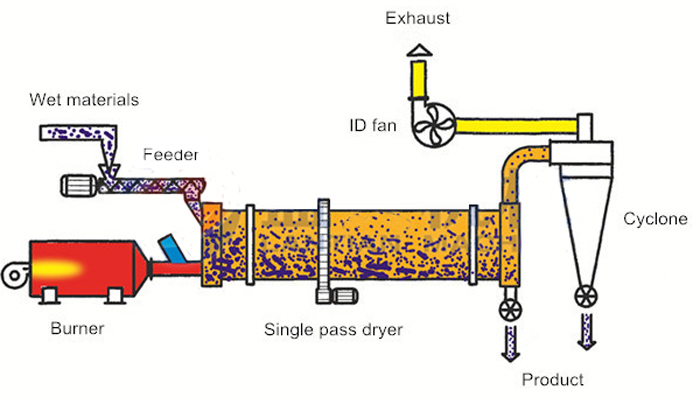

Using the unique scatter device, the coal slime dryer can scatter the cohesive coal slime and then make the drying process, which increases the contact area between the coal slime and the hot air and largely improves the heat usage ratio. With the 12% moisture content, the drying coal slim can be used as fuel directly, changing waste material into things of value.

1. It is used as the dryer of lignite, raw coal, semi coke, flotation coal and other materials in the coal industry;

2. Dry the blast furnace slag, gypsum, clay, limestone and viscidity mud in the construction industry;

3. Dry the metal concentrate, waste residue, gangue and so on in the mineral processing industry;

4. Dry the non-thermo sensitivity material in the chemical industry.

1. Largely reduce the moisture content of coal slime, broaden the sales channels and improve the economic benefits;

2. Solve the environment pollution problems "loss with water, fly with wind" caused by coal slime discard and air storage;

3. As the raw materials of briquette coal, drying coal slime serves for industrial boiler and resident life;

4. As the fuel of power plant foundry industry, drying coal slime can improve the fuel usage effect and economic benefits;

5. As the annexing agent of brick plant, drying coal slime can improve the hardness and compressive strength of bricks;

6. As the additive in cement plant, drying coal slime effectively improves the cement property;

7. Coal slime containing special ingredient can serve as chemical raw materials.

Slurry dryer price varies by the season, market statue and models. Please consult coal slime drying machine manufacturer before your purchasing.

Fote machinery is a professional coal slime drying machine manufacturer. With the 10%-15% coal and electricity consumption reduction, the reasonable slurry dryer price and 10%-15% production capacity improvement of one machine, the slurry dryer of Fote machinery is popular in the mining market. Welcome the arrival of new and old customers!

Our sales team is available to respond to any queries you might have on Fote. Get in touch using the details below:

High and New Industrial Zone, Kexue Revenue, ZhengZhou, China.

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

FTM has equipment installed throughout the world in are as such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern Asia.

Whatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

30 seconds for connecting customer service

30 minutes for getting technical answer

24 hours for getting free solution plan