Online Service Connection < 60s, Email Reply Time < 24h

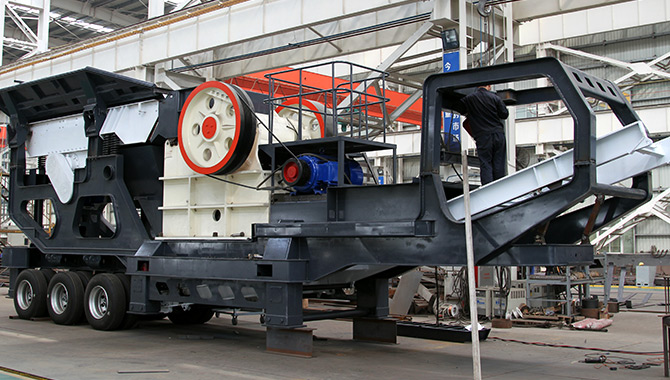

Besides the main crushing equipment of high-performance jaw crusher, mobile jaw crusher is also equipped with vehicular feeder and high-intensity vibrating screen. With advantages of short length, light weight, strong mobility and adaptability, flexible combinations and low materials transport cost, mobile jaw crusher will bring unexpected effect for the coarse crushing, fine crushing and sand making operations.

Without the limitation of fixed crushing site and high material transport costs, portable jaw crusher plant is a new type of stone crushing equipment that successfully realizes the on-site crushing and nearest operation. Mobile jaw crusher is mainly used in metallurgy, chemical industry, building materials and other industries, especially suitable for mobile crushing operations of multi materials on the highway, railway, water supply and power supply project.

1. It is easy to move and it covers small area. Crushing sites can be directly selected and it can be put into production once placed to the scene;

2. Portable jaw crusher plant has a higher crushing ratio;

3. Compared with other mobile crusher, mobile jaw crusher has higher crushing efficiency, production capacity and uniform granularity of finished product;

4. Self-driven way is more advanced and mobile jaw crusher has multiple functions;

5. Whatever the terrain condition is, mobile jaw crusher can reach any location of the workplace;

6. Compact chassis shortens the length of material transport;

7. A single application and multi combined utilization all can be competent;

8. Pre-screening function largely strengthens the processing capacity;

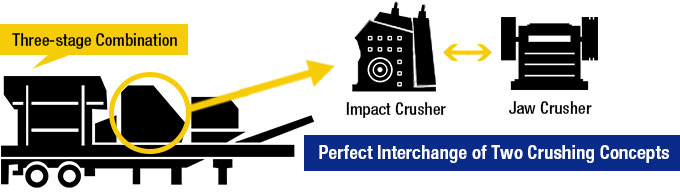

9. Unit mainframe exchange system satisfies customers' personalized demands.

10. Flexible parking function is conductive to the quick access to working statue.

1. Building materials

2. Concrete materials

3. Metallurgy, mining, coal mines

4. Refractory material crushing operation

5. Rocks, glass crushing

6. Construction waste

7. Stone crushing operation

8. Sand making materials crushing operation

9. Expressway materials crushing operation

Interchange System of Jaw Crusher and Impact Crusher

What you need invest is just the single equipment cost. In a short time, it realizes the interchange of different crushing units in the mining working site. The perfect match between the whole systems, wider application ranges and more comprehensive crushing functions all maximize the customers' benefits.

Do you want to know the portable jaw crusher plant price? Now please no hesitate to leave your email and demand on official website of Fote Machinery!

Our sales team is available to respond to any queries you might have on Fote. Get in touch using the details below:

No. 168 Wutong Street Zhengzhou, Henan, China.

| Model | FTM938HD86 | FTM1149HD98 | FTM1349HD110 | FTM1349HD125 |

| Transportation lenght(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Lenght(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial |

| Jaw Crusher | HD86 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge opening range | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m | B650×4m | B650×4m |

| Gensrt(optional) | 200KW | 250KW | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Model FTM938HD86 and FTM1149HD98

| Model | FTM938HD86 | FTM1149HD98 |

| Transportation lenght(mm) | 12600 | 13500 |

| Transportation Width(mm) | 2600 | 2700 |

| Transportation Height(mm) | 3870 | 4200 |

| Maximum Lenght(mm) | 12500 | 14000 |

| Maximum Width(mm) | 4100 | 4500 |

| Maximum Height(mm) | 4100 | 4900 |

| Weight(t) | 39 | 57 |

| tIRE Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD86 | HD98 |

| Maximum Feeding Size(mm) | 500 | 550 |

| Discharge opening range | 50-150 | 75-175 |

| Capacity(t/h) | 85-275 | 110-350 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m |

| Gensrt(optional) | 200KW | 250KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 |

Model FTM1349HD110 and FTM1349HD125

| Model | FTM1349HD110 | FTM1349HD125 |

| Transportation lenght(mm) | 14500 | 15200 |

| Transportation Width(mm) | 2800 | 2900 |

| Transportation Height(mm) | 4450 | 4500 |

| Maximum Lenght(mm) | 16100 | 16700 |

| Maximum Width(mm) | 5100 | 5100 |

| Maximum Height(mm) | 5000 | 5300 |

| Weight(t) | 55 | 65 |

| Tire Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD110 | HD125 |

| Maximum Feeding Size(mm) | 660 | 800 |

| Discharge opening range | 100-200 | 125-225 |

| Capacity(t/h) | 215-510 | 280-650 |

| Vibrating Feeder | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-10 | RCYD(C)-12 |

FTM has equipment installed throughout the world in are as such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern Asia.

Whatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

30 seconds for connecting customer service

30 minutes for getting technical answer

24 hours for getting free solution plan