Online Service Connection < 60s, Email Reply Time < 24h

Applied material: barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, silica sand, quartz, calcium carbonate.

Raymond grinding mill is suitable for the non flammable and explosive mining materials with less than 7 Mohs hardness and no more than 6% humidness, such as mineral stone or ores limestone, barite, calcite, silica sand, quartz, feldspar, talc, marble, calcium carbonate, dolomite, fluorite, clinker, gypsum, lime, bentonite clay, phosphate rock, manganese, titanium, copper ore, chrome ore, refractory material, graphite, slag, coal, biochar, zeolite, kaolin, calcite, avtivated carbon,etc. Raymond mill is also used in the high fine powder process of more than 300 materials in chemical and construction industries. The finished product size can be adjusted discretionarily from 80-325 meshes and finished product size of some materials can reach up to 600 meshes.

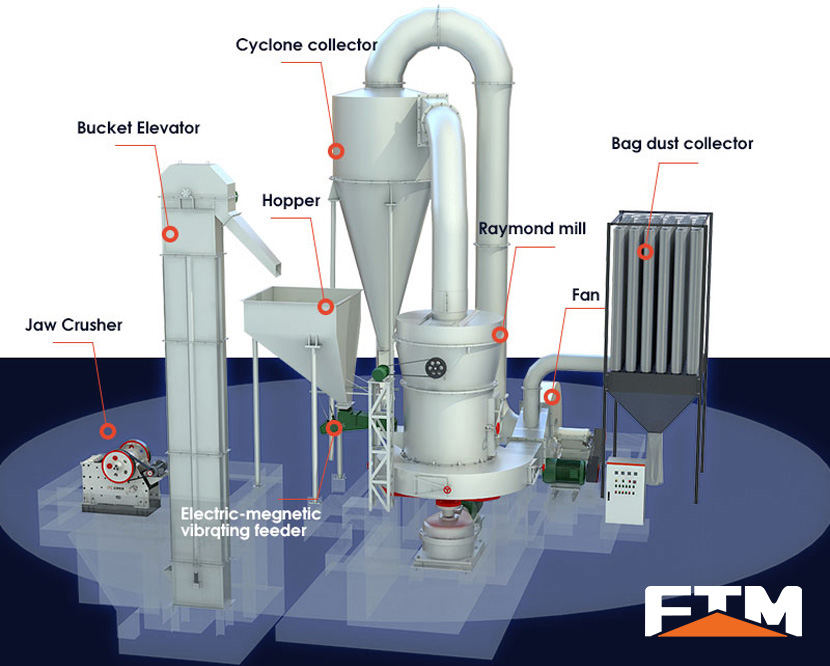

Powder grinding plant is generally composed of jaw crusher, bucket elevator, electro-vibrating feeder, mainframe and auxiliary engine of grinding mill, draught fan, dust-removing equipment, centralized electronic control and other equipment.

1. Large blokes of materials crushed by jaw crusher are lifted to storage silo by bucket elevator.

2. Electro-vibrating feeder uniformly, quantificationally and continuously sends materials to grinding chamber for grinding work. The grinded powder is sent into powder concentrator for separation with the help of air blower.

3. After the separation, unqualified powders are sent to grinding chamber for further grinding. Then the pipeline sends the qualified fine powders to storage silo. At last, qualified powders will be output from the discharge gate and these are finished powder materials.

We supply 3,4,5,6 rollers raymond mill to satisfy your different needs. The discharging size of powder can be 80 mesh, 200 mesh, 800 mesh, 1000 mesh, 45micron, 200 micron, 0.074mm, etc. We can provide you with a single raymond mill machine or a stone powder production line. The output powder passing rate is up to 99%. Made of high manganese steel, raymond mill parts are very durable. Of course, if replacement parts are needed later, we can provide them for you to let you use it with more confidence.

Fote machinery has all kinds of Raymond mill for sale, such as fluorite Raymond mill, bentonite Raymond mill, marble Raymond mill, talc Raymond mill, etc. You are welcomed to leave your message on our website directly or consult our online services for Raymond mill price.

Our sales team is available to respond to any queries you might have on Fote. Get in touch using the details below:

High and New Industrial Zone, Kexue Revenue, ZhengZhou, China.

| Model | 4525 | 4119 |

| Feeding Size(mm) | ≤30 | ≤25 |

| Output Size(mm) | 0.173-0.044 | 0.173-0.044 |

| Shift Output of Different Material Fineness(t) | 16-176 | 8-78 |

| Rotation Speed of Central Shaft(r/min) | 82 | 105 |

| Ring Diameter(mm) | 1770 | 1400 |

| Roller Diameter(mm) | 450 | 410 |

| Roller Height(mm) | 250 | 190 |

| Main Motor(kw) | Y315M-4-132 | Y280S-4-75 |

| Fan Motor | Y315M-4-132 | Y280S-4-75 |

| Analyzer Motor | YCT250-4A-18.5 | YCT200-4B-7.5 |

| Model | Output Size (mm) |

Shift output of different materia fineness(t) |

| 4525 | 0.173-0.044 | 16-176 |

| 4119 | 0.173-0.044 | 8-78 |

FTM has equipment installed throughout the world in are as such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern Asia.

Whatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

30 seconds for connecting customer service

30 minutes for getting technical answer

24 hours for getting free solution plan