Online Service Connection < 60s, Email Reply Time < 24h

Application area: slag industry, sandstone industry, building material, metallurgy industry, chemical industry, coal plants, mining industry

As one of the necessary drying equipment in the beneficiation processing, rotary dryer is widely used in the mining, metallurgy, chemical and cement industries for drying the industrial mineral, sand, quartz silica, raw ore, mineral powder, iron ore, mineral concentrate, chrome copper ore, coal, ore powder, slag, phosphate, bauxite, clay, limestone, gypsum, sawdust and so on. Rotary dryer is generally suitable for powder and granular material or other high moisture content materials and slowness and paste material formed by mixed material drying way. Material humidity can be reduced by 65%.

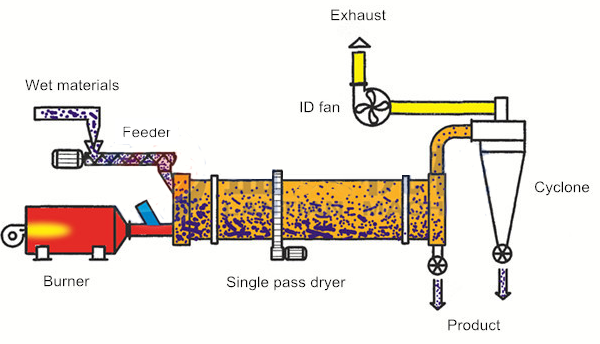

The mineral is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The material is added from the higher end, and the heating medium enters from the lower end, and is in countercurrent contact with the material. When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried, and then sent out through a belt or screw conveyor at the discharge end. In addition, dust collectors can also be used to reduce dust in the drying system.

Main types of rotary drying machine are: industrial mineral dryer, iron ore dryer, fly ash dryer, coal dryer, quartz sand dryer, gypsum dryer, phosphate dryer, mineral powder dryer, ore concentrate dryer, bauxite dryer, sand dryer, rotary drum dryer, sludge dryer, airflow dryer and so on.

With the domestic advanced production technology, the rotary drying machine developed by Fote machinery has its most obvious advantage of low energy consumption. The 30% lower energy consumption of Fote rotary drying machine largely saves the customers' production investment and strongly favored by large amount of customers.

Compared with traditional rotary drying machine, Rotary Dryer of Fote machinery has its obvious superiorities.

1. With less than 50 degrees centigrade discharging temperature, the finished product can be sent into material warehouse without the cooling step;

2. Without air leakage phenomenon, the sealing problem is solved in depth. The installation can be finished within 2 hours;

3. Compared with the 32% heat efficiency of traditional single-tube rotary drying machine, this kind of machine has 80% heat efficiency which is 48% improvement;

4. There are 50% reductions of floor area and 50% lower civil engineering investments contrast with traditional single-tube rotary drying machine

As a professional rotary dryer manufacturer, Fote machinery has the rotary dryer for sale. The equipment in Fote machinery has been strongly favored by its customers at home and abroad. To get the rotary dryer price, please contact us soon. Purchasing email: info@sinoftm.com

Our sales team is available to respond to any queries you might have on Fote. Get in touch using the details below:

No. 168 Wutong Street Zhengzhou, Henan, China.

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

FTM has equipment installed throughout the world in are as such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern Asia.

Whatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

30 seconds for connecting customer service

30 minutes for getting technical answer

24 hours for getting free solution plan