Want to know the price of Barite Mill? Contact us now!

With wide application range in industry field, barite is an important non-metal raw mineral material. Barite mill is the main equipment in the barite grinding mill plant.

The barite grinding fine powder can be used as the heavy agent of drilling mud and the crushing barite lump is the stone replacement of anti-radiation gravity wall materials. It can also serve as white pigment, painting, filler of rubber industry and paper-making industry, chemical medicine and so on.

Barite grinding mill is the grinding machine to grind the large barite stone to powder dust such as 80 mesh, 200 mesh, 300 mesh, 800 mesh, 45 micron, 200 micron, 0.074mm, etc. Barite mill is widely used in metallurgy, building materials, chemical and mining industries for grinding materials such as calcite, limestone, dolomite, bentonite, etc.

We supply different capacity barite mill to save your costs and maximize your benefits. We customize small capacity barite milling machine for small scale miner, such as 1 tph, 3 tph, 5 ton per hour, etc. We also provide large and medium capacity grinding plant for large mining company, such as 30 tph, 50 ton per hour, 100-200 tph, etc.

1. Raymond grinding mill: with the discretionary adjusted fineness, its general processing fineness is between 15 meshes and 425meshes.

2. HGM super fine grinding mill: with the discretionary adjusted fineness, its general processing fineness is between325 meshes and 2000meshes.

We can provide you with a single barite mill machine or a barite powder production line according to your different need.

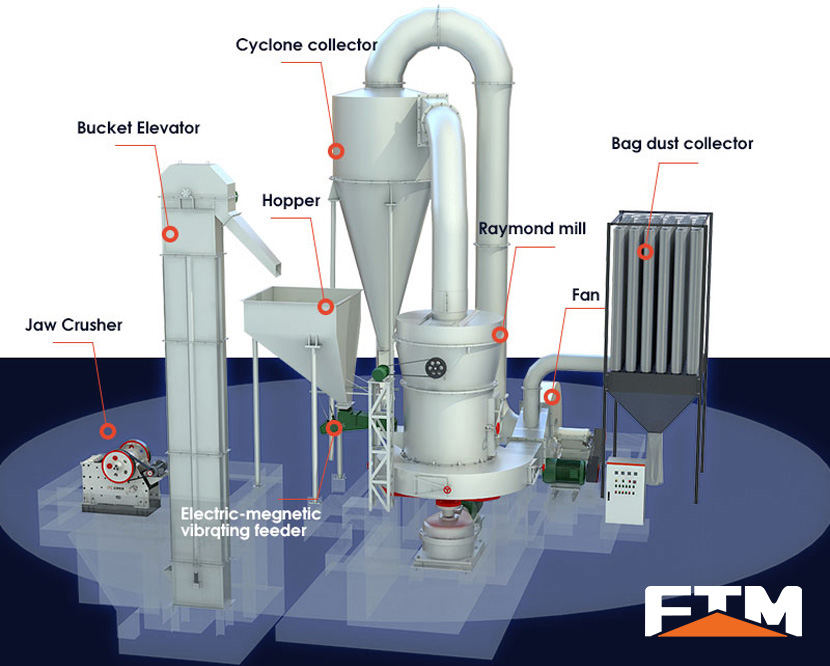

Powder grinding plant working porcess is: Raw material (block-shaped barite) ------ barite crusher------ bucket elevator------ raw material bin------ electro-vibrating feeder------raymond grinding mill------ powder packing machine

1. Large blokes of materials crushed by jaw crusher are lifted to storage silo by bucket elevator.

2. Electro-vibrating feeder uniformly, quantificationally and continuously sends materials to grinding chamber for grinding work. The grinded powder is sent into powder concentrator for separation with the help of air blower.

3. After the separation, unqualified powders are sent to grinding chamber for further grinding. Then the pipeline sends the qualified fine powders to storage silo. At last, qualified powders will be output from the discharge gate and these are finished powder materials.

The closed circulating ash system and circular flow of pressure and vacuum statue reduce the dust producing rate.

Made of super quality steel of important component and wear-resistant material, the barite grinding mill is durable and reliable.

Unsurpassable new design idea help produce uniform finished product whose sieve passing rate is 99%.

With the intelligent and centralized control electrical system, ultrafine grinding machine workshop can basically realize unmanned operation. Its repair is also convenient.

FTM has equipment installed throughout the world in are as such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern Asia.

Equipment: 2 micro powder mills with HXM-1021 model

Production Fineness: 800 meshes =D90,8-10T/H

VIEW MORE

Processing Materials: Quicklime

Production Capacity: 15t/h

VIEW MOREWhatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

30 seconds for connecting customer service

30 minutes for getting technical answer

24 hours for getting free solution plan