Our engineer can customize specific solutions according to your requirements.

Processing capacity: 1-150 ton/hour

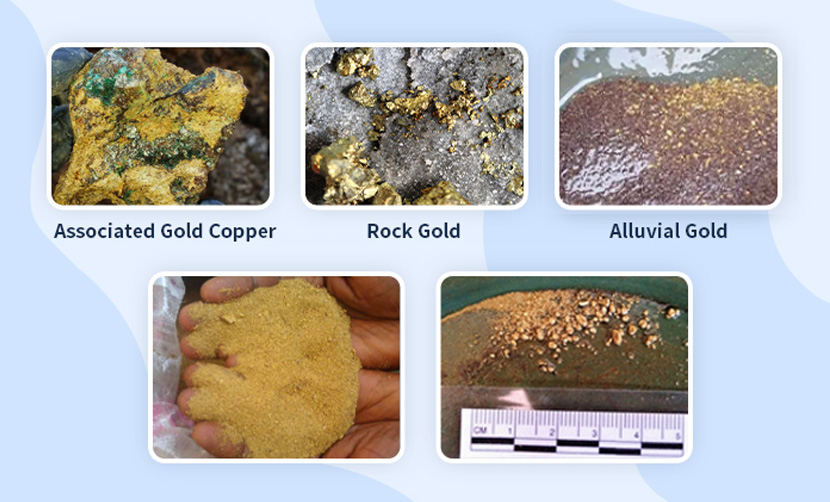

Applied material: gold stone, alluvial/placer gold, rock gold, gold mine, copper, silver, chrome, sulfide minerals, etc.

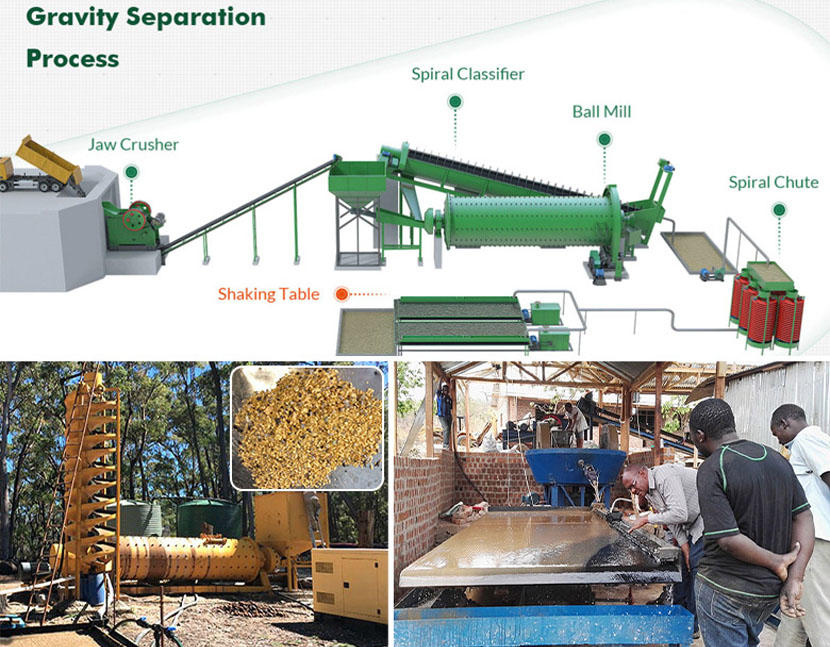

Main Equipment: jaw crusher, flotation machine, classifier, ball mill, shaking table. gold washing trommel screen etc.

Gold ore processing plant is mainly used for crushing, grinding, separating, washing, extracting gold ore and upgrade gold 90% in ore dressing industry. The methods for processing gold ore include Flotation Separation process and Gravity Separation process.

My company supply process plant for alluvial/placer gold process, rock gold process and associated gold mine process.

Hot sale capacity such as 1 tph, 3 tph 5 ton per hour (for small gold miner), 10 tph, 50 ton per hour (for medium large mining company)

Mainly Equipment: stone crusher, ball mill, shaking table, spiral classifier, spiral chute, etc.

Suitable Materials: alluvial/placer gold, rock gold, etc. The gold concentrate of placer gold ore has a high content and mostly exists in the form of sand grains. Therefore, gravity separation is often used when sorting. After pretreatment, desliming and washing of ore, coarse gold ore particles can be directly obtained.

Mainly Equipment: stone crusher, ball mill, flotation machine, spiral classifier,dryer, etc.

Suitable Materials: gold, copper ore, sulfide minerals, silver ore, lead ore, sulfide gold ore, gold-bearing polymetallic ore,etc.

Working Process: 1. Mineral is crushed by jaw crusher to crush the ore into a reasonable fineness. Place an impact crusher for further crushing, if necessary. After that the material will be sent to silos by the elevator.

2. The materials are evenly by feeder into the ball mill for the grinding process to 80-500 mesh.

3. The ores after fine grinding will enter into the spiral classifier to wash and classify the ore mixture.

4. After cleaning and grading, the ore will go through the flotation operation after being sent to the flotation machine by the mixing barrel.

5. The fine materials after being sorted by the thickener can get dry minerals after drying.

Gold Ore Processing Plant in South Africa

Mr. Peter is a mining manager who is looking for a 30 tph gold beneficiation plant for his 1.8ppm gold. My engineer recommended him the PE-250×400 Jaw crusher, Ф1830×6400 Ball mill, two 15 tph gold shaking table. Now the extraction of gold ore concentrates is improved by 69%.

We provide 100% factory price and maximum discount for you. Additionally, if you are new in this industry, we will provide professional suggestions and solutions for you.

You are welcome to inquire by chatting with online service or leave your whatsapp/ email on our website. We will contact you within 24hours after receiving your inquiry.

FTM has equipment installed throughout the world in are as such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern Asia.

Processing capacity: : 1200T/D

Applied material: : Natural Gold

VIEW MORE

Processing capacity: : 700t/d

Applied material: : Gold

VIEW MOREWhatever your requirements, you 'll find the perfect service-oriented solution to match your specific needs with our help.

30 seconds for connecting customer service

30 minutes for getting technical answer

24 hours for getting free solution plan